TRIF in Safety: What It Tells You, What It Doesn’t, and How to Really Measure Workplace Risk

Introduction: TRIF Isn’t the Holy Grail

TRIF — Total Recordable Injury Frequency — is the metric everyone throws around in safety meetings. One glance at a low TRIF, and management smiles. But let’s be honest: TRIF doesn’t tell the full story, and relying on it exclusively is like judging a construction site by how shiny the helmets are.

Yes, it’s required for COR prequalification and some client contracts, but if you’re only monitoring TRIF, you might be missing near-misses, unsafe conditions, and cultural red flags that precede the next reportable incident.

What TRIF Measures

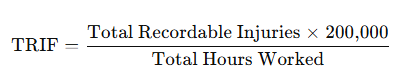

TRIF is calculated as:

Total Recordable Injuries: fatalities, lost-time injuries, restricted work, medical treatments

200,000: standard number of hours to normalize across company size

TRIF is useful for trend analysis across sites and industries. A sudden spike can indicate a systemic issue, while a downward trend may suggest improved safety.

The Limitations of TRIF

1. Lagging Indicator

TRIF only measures what’s already happened.

By the time a high TRIF appears, the underlying issues have often been present for months.

Like looking in the rearview mirror while driving a dump truck — you can see the potholes, but you’ve already hit some.

2. Severity Blind

TRIF treats all recordable injuries equally. A finger pinch is counted the same as a broken leg.

This can create false confidence: low TRIF doesn’t mean low risk, just low reporting.

3. Influenced by Reporting Culture

If crews underreport injuries to look good for audits, TRIF becomes meaningless.

Conversely, a site with honest reporting may look worse than one that sweeps incidents under the rug.

4. No Context for Near-Misses

Near-misses are gold. They’re the red flags that predict bigger incidents. TRIF ignores them entirely.

Industry Examples: Why TRIF Can Be Misleading

Residential Construction: crews might tolerate minor cuts and scrapes without reporting. TRIF looks artificially low.

Energy (Oil & Gas): rigorous reporting culture, high regulatory scrutiny. TRIF might spike frequently, even with excellent safety management, because every scratch is documented.

Landscaping: small crews, informal tracking. TRIF is often non-existent or irrelevant without additional oversight.

Going Beyond TRIF: What Really Measures Safety

Leading Indicators

Near-miss reports, hazard observations, safety meetings, toolbox talk attendance; proactively show how well your program is working before injuries occur

Compliance & Audit Data

Audit scores, documentation completeness, training records

Shows if systems are actually implemented

Safety Culture Metrics

Worker surveys, engagement, reporting frequency

Culture predicts behavior more than any formula

Incident Investigations & Corrective Actions

Quality of investigation matters more than the number of injuries

Ensures issues are addressed, not just recorded

Practical Takeaways for Managers

Don’t obsess over TRIF — use it as one part of a bigger picture

Track leading indicators — they give you time to act

Audit and coach regularly — quality over quantity

Normalize honest reporting — low TRIF can be a warning, not a badge of honor

Conclusion

TRIF is a useful benchmark metric, but it’s far from the full story. Companies in Alberta, BC, and Saskatchewan should treat it as a piece of the puzzle, combined with leading indicators, audits, incident investigations, and culture metrics.

At Cascade Safety Solutions, we help businesses go beyond TRIF to track meaningful safety performance, reduce incidents, and improve compliance.

Ready to understand your company’s true safety performance? Book a free 20-minute consult via Microsoft Teams, or in-person if you’re in Calgary.